5 Criteria of a Quality Precision Machining Manufacturer

What makes a quality precision machining manufacturer stand out from its peers? With so many manufacturers out in the market, it might be difficult to distinguish the good ones from the bad. Below are 5 typical traits you would expect to see in a quality precision machining manufacturer.

1. Experienced and Stable Core Managerial and Technical Team:

A company with an experienced managerial, technical and manufacturing team that has a wealth of knowledge is vital. The more experienced the shop is the more hands-on they can be with new projects. Experienced manufacturing engineers are often able to quickly identify and offer alternate solutions when problems arise based on previous ordeals in projects. They are even able to help design your product to make it "design-for-manufacture" friendly, allowing an OEM to save time and money on assembly. More importantly, assist an OEM to stay ahead of competition by achieving faster time-to-market for their new products.

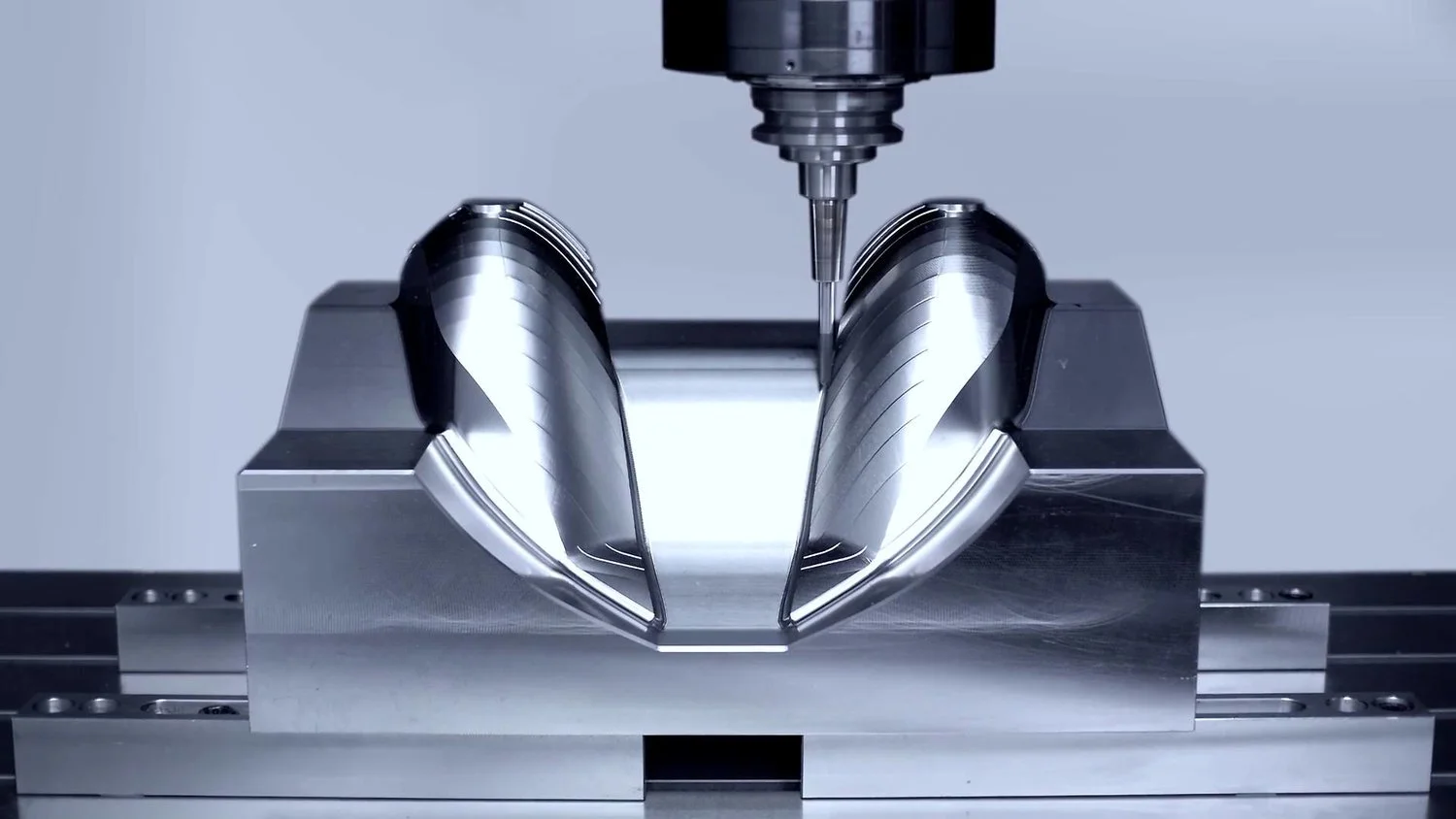

2. Tooling and Equipment:

Tooling is what defines a machine shop’s capabilities as well as their limits. A quality precision machine shop is only as good as their equipment and their technical team. Good questions to ask them would be:

- What equipment and software does the machine shop carry?

- When was the last time the equipment or software was updated?

- Do they have high-speed precision and progressive dies? And if so, what sizes can they handle?

It is important to have the correct equipment and technology to create your products. Every new generation and releases of CNC equipment will normally be more precise, programmable and faster than the generation prior. In terms of software, a quality precision machine shop would be well versed in different types of software in order to manufacture and edit model designs when needed. A good sign of a quality precision machining manufacturer would be their continuous effort to look for ways to improve and maintain their tooling and upgrading to more advanced technology and equipment.

3. Quality Control:

Quality control is an important factor for any manufacturer's capabilities. A great way to learn about a factory's quality control process is to look at their certifications and auditing reports. Factories should at least obtain an ISO 9001 certification which confirms quality management. If they want to take their quality controls a step further they will also obtain an ISO 14001 certification for environmental quality management, ensuring that products and waste are environmentally responsible. Additionally, a quality machining shop is often credited with an OHSAS 18001 certificate which demonstrates commitment of the factory to adhere to rigorous occupational health and safety standards and best practices.

It is just as important to review the shops internal audit reports from operations to management, to warrant that all levels of quality are met. Factories should have detailed and accurate information on each equipment being used to detect specification accuracy, control standards, and response measures to keep rejection rates low and production yield high. A quality precision machine shop that is confident and proud of their products would be open to discuss their failure rate as well as their objectives and goals in reducing the failure rate to more suitable levels.

4. Ability to Achieve a Tight Tolerance:

Being within the required tolerance is very important. Tolerance is the clearance range in size a component needs to be within in order to fit into another component. For example, a metal piece is measured to be 8.25” but it can not be any larger than 8.255”, which means that the tolerance level is .005". If it's too small, the metal piece will not reach across the entire component it is being inserted in and if it is too big the metal piece will not fit in its designated location. More and more industrial applications require increasingly tighter tolerances. The aerospace and medical industries, for example, are well known for its stringent tolerance requirements that call for a quality precision machine manufacturer. These levels challenge machine shops to continuously deliver quality products within their specified tolerance levels, in order to meet the essential overall tolerance a final product requires.

5. Agility, Flexibility and Being Able to Respond to Customers’ Demand Changes:

A quality precision machine shop will deliver the manufactured goods on time and on schedule, as was agreed. The shop should inform the client of any event that arises if it should alter the expected delivery date whether it is good or bad news. Nothing is more frustrating than a missed product delivery. It is absolutely critical that the precision machine shop you choose to work with is agile, flexible and highly responsive to your demand changes. If you are looking to save time and money, a machine shop that offers both primary (for example, laser cutting, CNC machining, metal stamping, etc.) and secondary services (for example, power coating, tunnel cleaning, sub-assembly, etc.) in-house is essential. This eliminates the shifting of your product from one manufacturer to the other, dismissing room for error, time lapses and extra cost on shipping and handling.

In a nutshell, a quality precision machine manufacturer will have an abundance of experience in manufacturing, good upkeep of tools and continuous advancement, superior quality control measures, be able to stay within their tolerance levels, and lastly, effective schedule control and order change management. Are we missing any other important criteria? Please comment below and share your thoughts! Don’t forget to check out our other blogs!