Laser Cutting Applications in Precision Machining

Laser cutting in precision machining is a high-tech machine that is used to precise-cut both metal and non-metal materials. It has gained tremendous popularity in both consumer electronics and industrial sectors. The hi-tech industry is increasingly replacing or complementing conventional cutting technology with laser cutting; while manufacturers gaining competitive advantages by implementing laser cutting machinery.

In this blog, we take a quick look at laser cutting applications in precision sheet metal fabrication.

Laser Cutting Basics

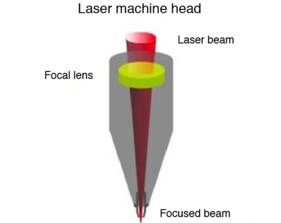

A laser cutter is made up of a laser resonator which produces the high-power beam and a mechanical system that moves the laser over the material in a computer-controlled pattern. In its simple form, a focused lens is used to concentrate all of the energy onto a precise point to remove the material (by melting, burning, and vaporizing away the material). An assist gas, such as oxygen or nitrogen, is then directed through a nozzle to expel the molten material, leaving an edge with a high-quality surface finish. This beam is normally focused and intensified by a lens to a very small spot of about 0.001 inches (0.025 mm) to create a very intense laser beam. The position of the laser beam is precisely controlled by a computer program - also known as CNC code - driving the X and Y axes of the CNC machine. The CNC computer adjusts the power of the laser beam to ensure that the laser power is optimized for a certain cutting speed.

In comparison, the traditional way in a precision machining shop to cut sheet metal is with a stamping or punch press. It is a slower process which requires a separate tool for each type of cut. A laser cutter uses a computer-guided beam and can precision cut virtually any shape. The laser cutting process is able to offer superior cut-edge quality with no rough edges.

Laser Cutting Advantages

Advantages of laser cutting over traditional mechanical cutting include:

Flexibility:

Laser system handles profiles from the simplest of components to shapes of high complexity. With computer added peripherals a laser cutting system also allows one to create intricate designs and highly detailed cuts in sheet metal materials.

Precision:

With its laser-focused precision, the process is capable of holding close tolerance, often to within 0.001 inches (0.025 mm). Newer laser cutters have approached a positioning accuracy of 10 micrometers (0.01mm).

Free of contamination:

The laser creates a high-power beam to cut through the material. During the process, there is no part of the laser system in contact with the material.

Simplification:

Traditional stamping or punch press leaves rough edges or burrs that workers must grind smooth afterward but a laser cutter leaves a smooth edge that needs no further work. It prevents or reduces the chance of warping the material that is being cut. This saves time and labor costs, making this technology a cut above traditional CNC stamping machines.

Efficiency and rapid turn-around: Laser cutting allows one to cut complex shapes without the need for tooling or fixture and at a similar or faster speed than other cutting methods. With zero tooling and fixture costs, laser cutting is a highly attractive and economical means of sheet metal fabrication.